“Achieved 99.54% Dissolved Oxygen Removal from Water”

The main aim of the HiGee DeAerator system is to remove the dissolved oxygen from boiler feed water. A traditional De-aerator unit is no match for the HiGee system when compared with any parameter of cost, efficiency, maintenance and ease of operation.

- The model shown below is a 2-Ton/Hr Deaeration Skid based unit designed to carry out experiments using various combinations of facilities provided on the skid, to efficiently and economically deaerate water.

- The system built includes a Hi-Gravity process intensification unit called HiGee, a 120 Kw heating system with thyristor control, High capacity Vacuum facility, a cooling system, a VFD for speed control of HiGee rotor and an inbuilt Nitrogen Carrier System.

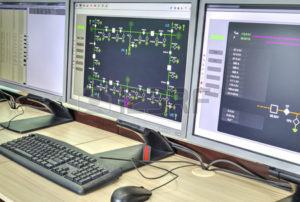

- The entire unit is a SCADA based PC-PLC control system provided with printing and display facilities This is a one of its kind test skid with various facilities, provided with Auto and Manual controls.

The HiGee De-Aerator has varied applications including –

- Soft drink industry

- Boiler feed

- Alcohol industry

SUPPLIED DEAERATION UNIT WITH CAPACITY 20 TPH

CAPABLE TO MANUFACTURE UNIT WITH CAPACITY 200 TPH